|

Dalian Baili Machine Tools Co.,Ltd

|

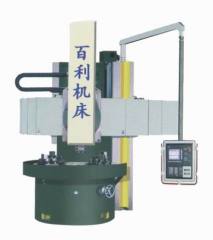

CK5120 CNC Single Column Vertical Lathe

| Special Groups: |

CK5120 CNC Single Column Vertical Lathe (1)

|

| Place of Origin: | Liaoning, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

CK5120 CNC Single Column Vertical Lathe,vertical lathe,cnc vertical lathe,Single column vertical lathe,Double column vertical lathe,cnc lathe machines

CNC Vertical Lathes

1.This series machine is suitable for finely and roughly turning cylinder and inner hole, inner and outer taper, surfacing, grooving, threading and curving of the ferrous, nonferrous metal and some kinds of non-metal materials with carbide and porcelain tools.

2.This series machine is divided into high-speed type, standard type and heavy-duty type.

3.The maximum speed can be 2000m/min when in high-speed turning. When the head is in high-speed movement, head in horizontal direction, and vertical rapid movement speed can be 12m/min.

4.The main drive adopts AC spindle servomotor within two steps (ZF gearbox, Germany). The high-speed rotating workpieces are balanced in static or dynamic pattern. Transmission gears with 5 grade precision are specially grounded to implement high efficient transmission, lower noise and smooth running in high speed turning.

5.Feed system is driven by AC servomotor which is connected with ballscrew by flexible couple to implement clearance-free transmission and high precision turning.

6.The columns, whose thermal symmetric construction, is calculated by finite element method, stand on table base. Effective vibration-insulated method is adopted to ensure high rigidity and strong anti-vibration ability.

7.The table is thermal-symmetric construction. The spindle is centered by high-precision double-row short cylindrical roller bearing whose radial clearance can be adjusted. With large high-precision thrust ball bearing on axial direction as rolling guideway, and oil temperature cooling device, the table has high swiveling precision, larger load ability and smaller deformation.

8.Linear dual-direction roller guideway is applied to ensure high effective transmission and good precision reliability in heads and ram feed movement.

9.CNC system is SEMENS or FANUC system, and other CNC system is also can be provided on customers?special requirements.

10.Chip conveyer and half-closed guide are also equipped by costumers' reguirements.

11.On customers' requirement, the followings can be supplied: Magazine, built-in tool setting device, boring & milling, table indexing and feed, grounding cooling device, left head and whole-loop control, etc.

1.This series machine is suitable for finely and roughly turning cylinder and inner hole, inner and outer taper, surfacing, grooving, threading and curving of the ferrous, nonferrous metal and some kinds of non-metal materials with carbide and porcelain tools.

2.This series machine is divided into high-speed type, standard type and heavy-duty type.

3.The maximum speed can be 2000m/min when in high-speed turning. When the head is in high-speed movement, head in horizontal direction, and vertical rapid movement speed can be 12m/min.

4.The main drive adopts AC spindle servomotor within two steps (ZF gearbox, Germany). The high-speed rotating workpieces are balanced in static or dynamic pattern. Transmission gears with 5 grade precision are specially grounded to implement high efficient transmission, lower noise and smooth running in high speed turning.

5.Feed system is driven by AC servomotor which is connected with ballscrew by flexible couple to implement clearance-free transmission and high precision turning.

6.The columns, whose thermal symmetric construction, is calculated by finite element method, stand on table base. Effective vibration-insulated method is adopted to ensure high rigidity and strong anti-vibration ability.

7.The table is thermal-symmetric construction. The spindle is centered by high-precision double-row short cylindrical roller bearing whose radial clearance can be adjusted. With large high-precision thrust ball bearing on axial direction as rolling guideway, and oil temperature cooling device, the table has high swiveling precision, larger load ability and smaller deformation.

8.Linear dual-direction roller guideway is applied to ensure high effective transmission and good precision reliability in heads and ram feed movement.

9.CNC system is SEMENS or FANUC system, and other CNC system is also can be provided on customers?special requirements.

10.Chip conveyer and half-closed guide are also equipped by costumers' reguirements.

11.On customers' requirement, the followings can be supplied: Magazine, built-in tool setting device, boring & milling, table indexing and feed, grounding cooling device, left head and whole-loop control, etc.

Related Search

Single Column Vertical Lathe

Vertical Lathe

CNC Lathe

Vertical Turning Lathe

Cnc Lathe Machine

Cnc Precision Lathe

More>>

.jpg)

.jpg)